Aerospace

Vacuum Drying for Aerospace: Moisture Control, Compliance, and Flight-Ready Performance

Overview

Aerospace components must meet the most demanding standards in engineering — and moisture is a hidden threat that compromises materials, adhesives, coatings, and electronics. Whether you're producing carbon fiber airframe parts, ceramic insulators, cable harnesses, or satellite systems, residual moisture and volatiles can lead to delamination, dimensional drift, or in-orbit outgassing.

iDRY vacuum drying systems give aerospace manufacturers complete control over internal moisture, surface prep, and outgassing — with repeatable, spec-compliant performance.

⚙️ How iDRY Vacuum Drying Works

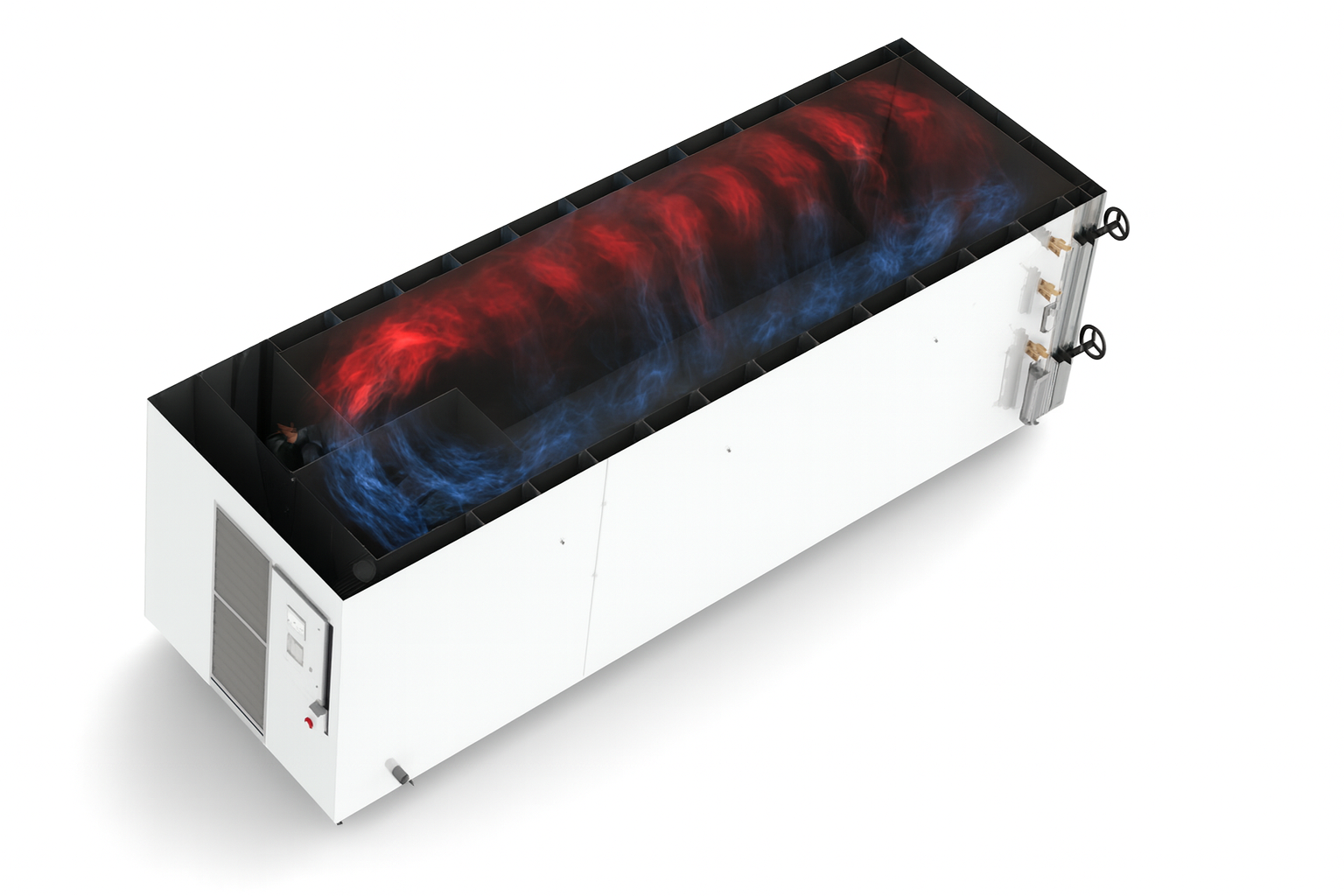

iDRY uses deep vacuum to reduce the boiling point of water and other volatiles inside parts. Under vacuum, moisture is removed gently and thoroughly — even from internal structures, honeycomb cores, or multi-layer assemblies.

This process supports precise drying of components before bonding, coating, assembling, or packaging — without warping, overheating, or contamination.

✅ Key Benefits:

Moisture removal at low temperatures for heat-sensitive materials

Supports NASA/ESA outgassing compliance (ASTM E595)

Enables strong bond lines and void-free adhesives

Ensures dimensional stability in vacuum and thermal cycling

Uniform drying across complex geometries and composite layers

Fully enclosed chamber with data logging and QA traceability

Ideal Aerospace Applications:

Carbon fiber panels, ducts, and fairings

Honeycomb structures and bonded assemblies

Satellite components and thermal blankets (MLI)

Cable harnesses and foam insulation

Ceramics, polymers, and aerospace-grade adhesives

Additive manufactured parts (metal or polymer)

Flight hardware drying and vacuum bake-out

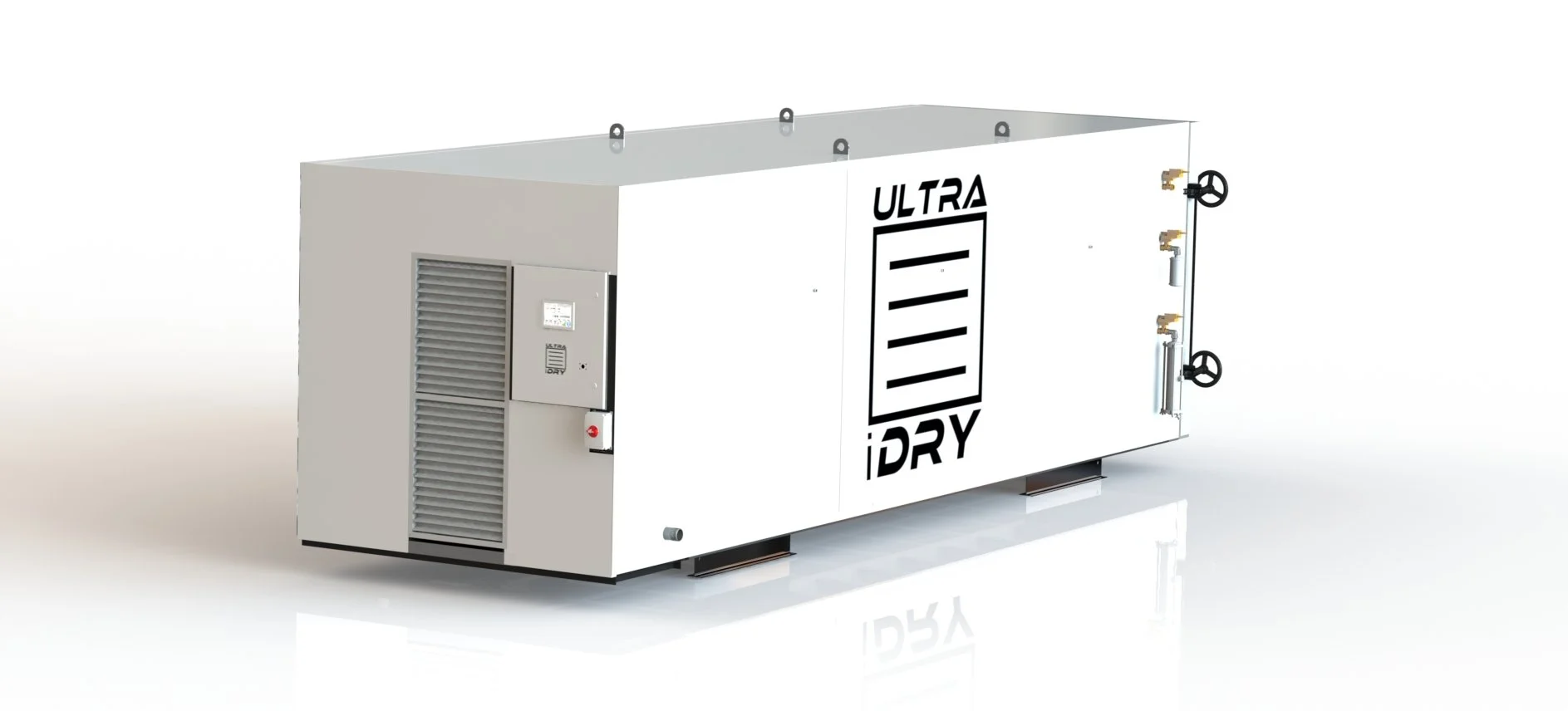

iDRY Ultra Vacuum Dryer – Aerospace & Advanced Materials

Precision Drying for Critical Aerospace Applications

The iDRY Ultra is an advanced vacuum drying system designed to meet the extreme quality and reliability demands of the aerospace industry. By combining vacuum technology with precise thermal control, the iDRY Ultra enables complete control of residual moisture content in sensitive components, composites, and specialty materials—at any temperature required by your process.

Whether drying carbon fiber laminates, composite structures, adhesives, or critical components, the iDRY Ultra ensures uniform results without thermal degradation. Unlike conventional ovens, the vacuum environment allows moisture removal at significantly lower temperatures, preserving the structural integrity, strength, and performance of advanced aerospace materials.

Key Benefits

Controlled Residual Moisture – Achieve any moisture or outgassing target at any temperature setpoint.

Material Integrity – Low-temperature drying prevents thermal damage, resin breakdown, or warping.

Process Flexibility – Customizable cycles for composites, adhesives, ceramics, and metal parts.

Enhanced Performance – Eliminate trapped moisture and volatiles that can compromise aerospace reliability.

Scalable & Proven – Available in batch systems at a price that allows for multiple units for scale.

The iDRY Ultra delivers precision vacuum drying that meets the stringent standards of aerospace, defense, and advanced manufacturing—where performance, safety, and reliability cannot be compromised.

-

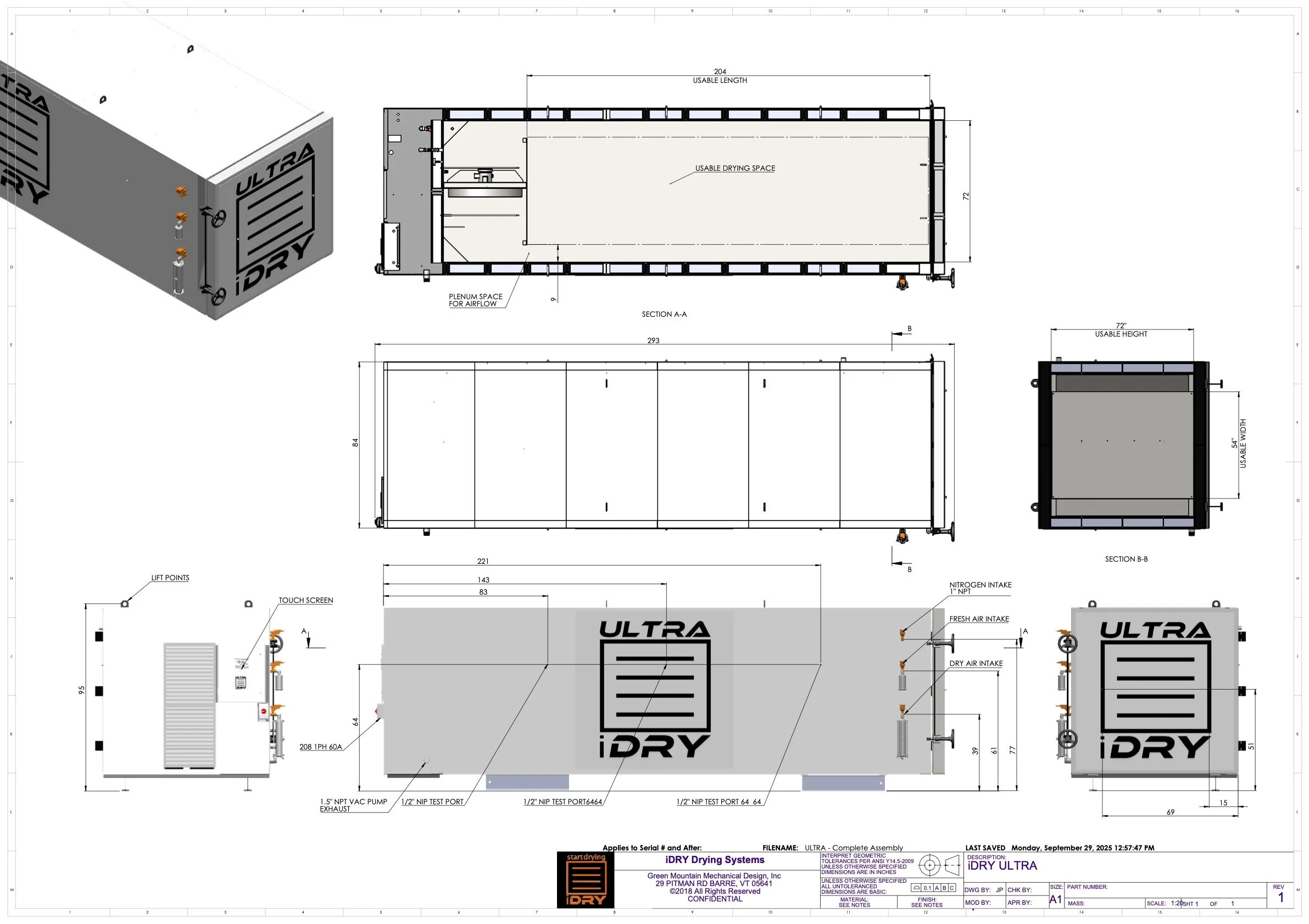

Capacity volume: 460 cubic feet

Power Requirement: 208-240VAC, 1PH, 60A (Electric)

Fully Reversible Fan: 2HP Kiln Duty Motor

Heat Power: 6kw

Humidity Sensor: Capacitive

Temperature Sensor: RTD

Loading: Hand, Tray or Forklift loaded

Max Temp: 180F

Controls: PLC w/ HMI TouchScreen

Total Weight of Equipment: 14,000lbs -

4-6 weeks Lead time

Shipped via Flatbed trailer

-

Non-stick airflow optimized self stacking trays