Food Products

Vacuum Drying for Food: Shelf Life, Flavor, and Efficiency

Overview

Producers of fruits, vegetables, herbs, proteins, and specialty ingredients face a persistent challenge: conventional dehydration can damage texture, color, nutrients, and shelf life.

iDRY’s vacuum dehydration systems offer a precise, low-temperature solution — preserving quality while dramatically reducing drying time and energy use.

“With iDRY, we cut drying time by more than half and maintained bright color and flavor in our fruit powders. We’re producing more, wasting less, and adding shelf-stable SKUs.”

— Natural Food Processor, Pacific Northwest

⚙️ How iDRY Vacuum Drying Works

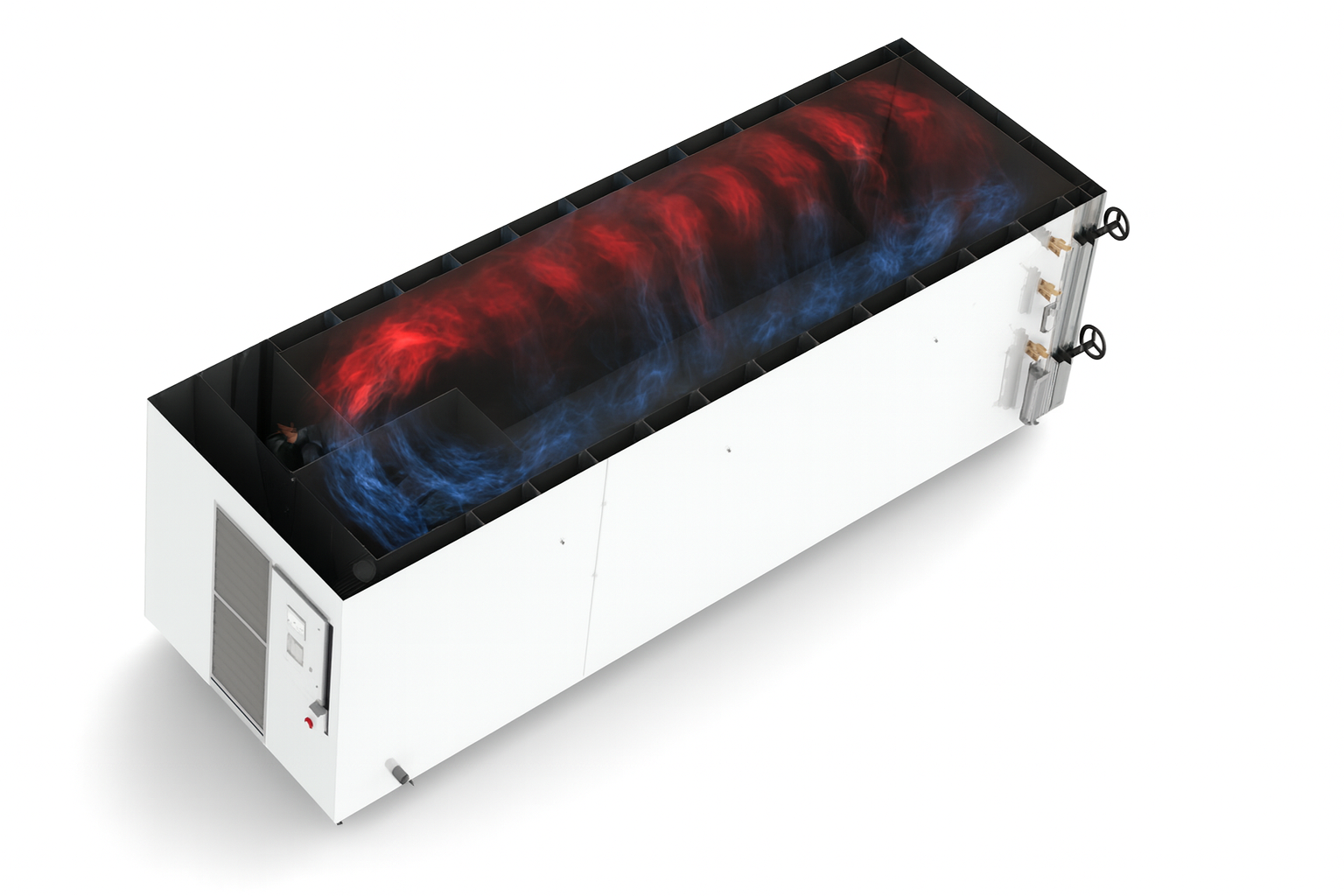

iDRY systems use deep vacuum to lower the boiling point of water inside food materials. This allows for moisture removal at significantly lower temperatures — ideal for preserving color, flavor, aroma, nutrients, and structure.

Airflow and heat are precisely controlled to dry uniformly and gently — even for dense or delicate ingredients.

✅ Key Benefits:

2x–5x faster drying than hot air drying

Gentle, low-temp dehydration = better flavor, color, and nutrient retention

Ideal for powders, snacks, extracts, and high-value ingredients

Fully enclosed chamber = low risk of contamination

Touchscreen controls with automated batch cycles

Built-in moisture monitoring and batch data logging

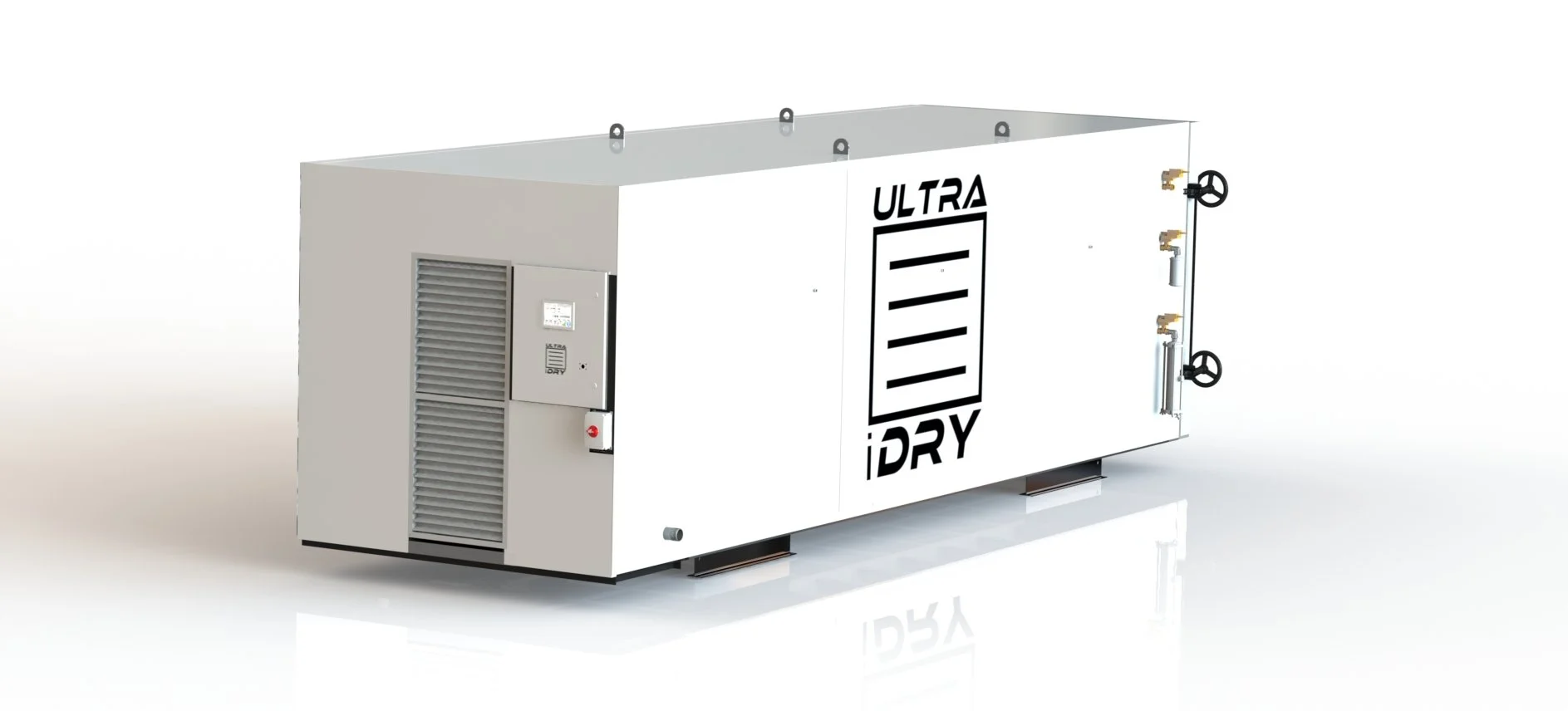

iDRY Ultra Vacuum Dryer

Unlock the future of food preservation.

The iDRY Ultra is a next-generation vacuum drying system engineered to achieve any target water activity (aᵥ) at any drying temperature—giving you complete control over shelf stability, flavor, texture, and nutritional integrity.

By combining vacuum technology with precise thermal management, the iDRY Ultra gently removes moisture without exposing foods to the high heat and oxidative stress of conventional drying or the cellular destruction caused by freeze drying. Fruits stay vibrant, vegetables retain their nutrients, proteins hold their natural structure, and sensitive bioactives remain potent.

Customizable outcomes – dial in exact water activity levels to meet regulatory and product-specific needs.

Low-temperature drying – preserve color, aroma, and phytonutrients even in delicate products.

Nutritional protection – minimize degradation of vitamins, enzymes, and functional compounds.

Versatile applications – from premium dried fruits and vegetables to nutraceuticals, proteins, dairy, pet food, and beyond.

Scalable design – proven vacuum drying technology available at affordable prices so you can start small and grow BIG.

The iDRY Ultra transforms food drying from a compromise into a precision process—where quality, nutrition, and safety are preserved at the highest standard.

-

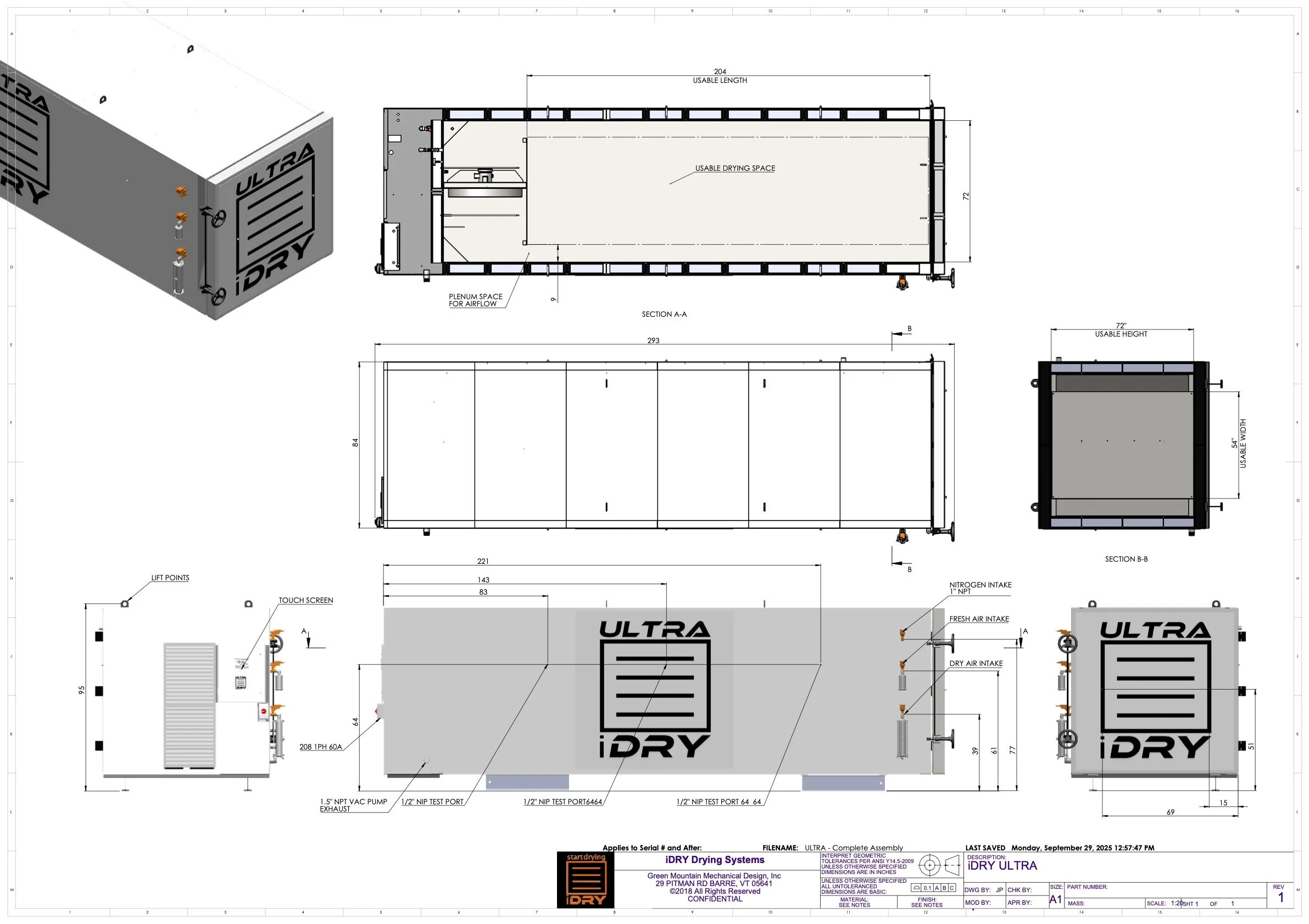

Capacity volume: 460 cubic feet

Power Requirement: 208-240VAC, 1PH, 60A (Electric)

Fully Reversible Fan: 2HP Kiln Duty Motor

Heat Power: 6kw

Humidity Sensor: Capacitive

Temperature Sensor: RTD

Loading: Hand, Tray or Forklift loaded

Max Temp: 180F

Controls: PLC w/ HMI TouchScreen

Total Weight of Equipment: 14,000lbs -

4-6 weeks Lead time

Shipped via Flatbed trailer

-

Non-stick airflow optimized self stacking trays