Carbon Fiber & Polymers

Vacuum Drying for Carbon Fiber & Polymers: Strength, Stability, and Speed

Overview

Manufacturers of carbon fiber and polymer-based components face a common production bottleneck: residual moisture and volatiles trapped after layup, infusion, or curing. Left unchecked, this leads to outgassing, voids, poor bond lines, and dimensional instability.

iDRY vacuum drying systems offer a fast, low-temp drying solution that removes moisture and residuals without damaging fibers, distorting geometry, or over-curing parts.

“iDRY gave us complete control over post-cure moisture. It shortened our cycle, improved bond integrity, and helped us meet strict aerospace outgassing specs.”

— Process Engineer, Advanced Composites OEM

⚙️ How iDRY Vacuum Drying Works

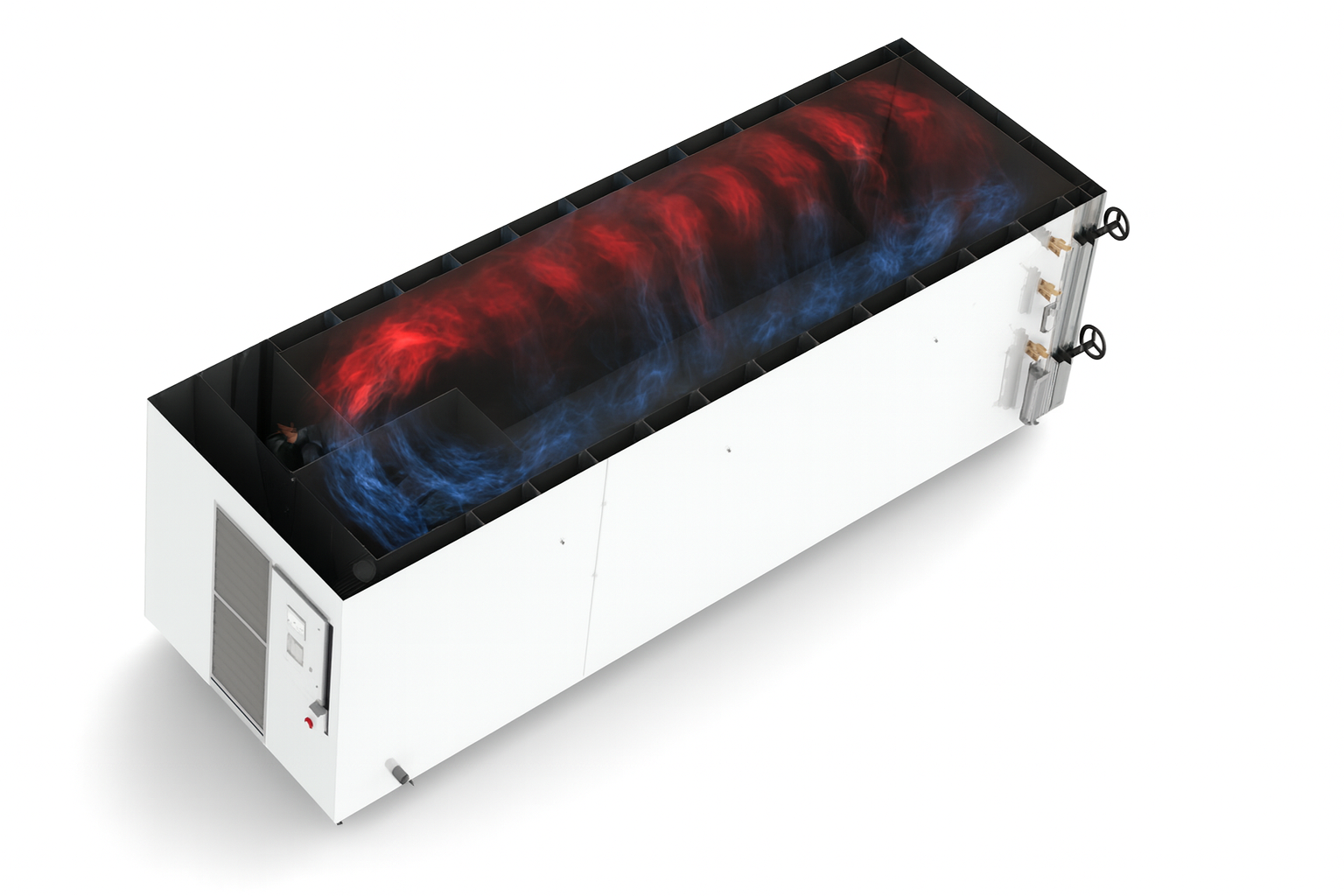

iDRY systems lower the boiling point of moisture inside materials using deep vacuum. This allows internal water and volatile compounds to be removed at lower temperatures — ideal for carbon fiber laminates, thermoset polymers, and complex parts.

Reversible airflow ensures even drying across part surfaces, reducing the risk of internal pockets, incomplete dry-out, or edge effects.

✅ Key Benefits:

Low-temp drying avoids resin softening, deformation, or delamination

Ideal for post-cure moisture removal, surface prep, or pre-bonding

Prevents blistering, outgassing, and void formation

Supports precise drying of infused panels, layups, and shaped parts

Compatible with aerospace, automotive, marine, and industrial specs

Full-cycle data logging for QA, traceability, and compliance

Applications Include:

Carbon fiber tubes, panels, and honeycomb cores

Vacuum-infused or resin-transfer molded (RTM) parts

Glass fiber or hybrid composites

Thermoplastic or thermoset polymers (epoxies, polyesters, vinyl esters)

3D-printed polymer components

Composite battery enclosures, fairings, ducts, and structural skins

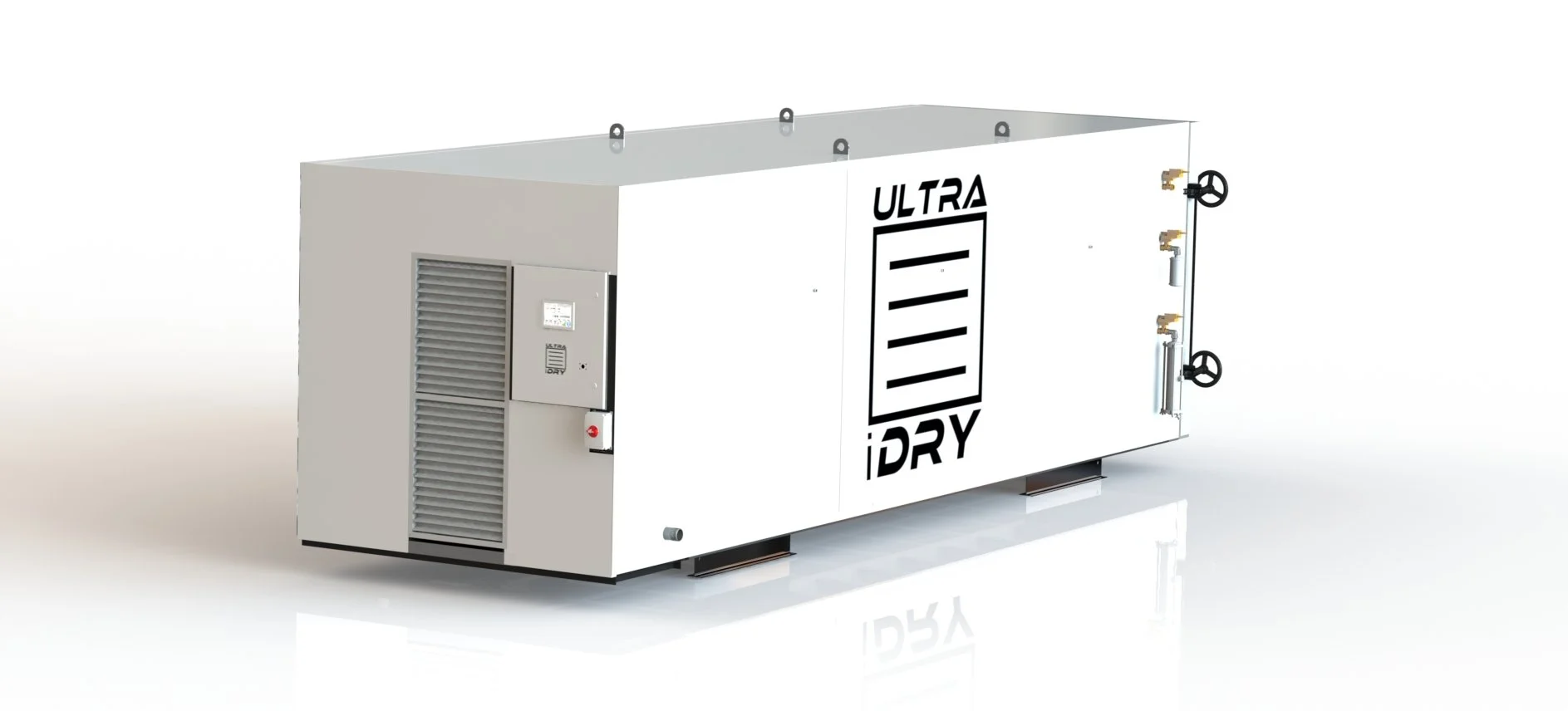

iDRY Ultra Vacuum Dryer – Carbon Fiber & Polymers

Precision Drying for High-Performance Composites

The iDRY Ultra is a vacuum drying system engineered specifically for carbon fiber, polymer composites, and advanced materials where moisture, trapped volatiles, and residual solvents can compromise performance. By combining a unique patented vacuum technology with precise low-temperature control, the iDRY Ultra ensures uniform, repeatable drying without thermal damage to sensitive fibers, resins, or matrix structures.

From aerospace-grade laminates to industrial carbon tubes and high-performance polymers, the iDRY Ultra delivers the ability to achieve any target residual moisture level at any process temperature, preserving the structural integrity and functional properties of the material.

Key Benefits

Moisture & Volatile Removal – Eliminate water, solvents, and entrapped gases to ensure stable, high-strength composites.

Low-Temperature Capability – Protects resin systems and fiber strength by avoiding thermal degradation.

Process Consistency – Achieve repeatable dryness specifications across batches and component sizes.

Enhanced Performance – Improves bonding, dimensional stability, and long-term durability of composites.

Scalable Design – Systems available for R&D labs, pilot production, and full-scale manufacturing lines.

The iDRY Ultra is built to meet the demands of modern composite manufacturing, enabling manufacturers to push the boundaries of carbon fiber and polymer applications in aerospace, automotive, energy, and advanced industrial markets.

-

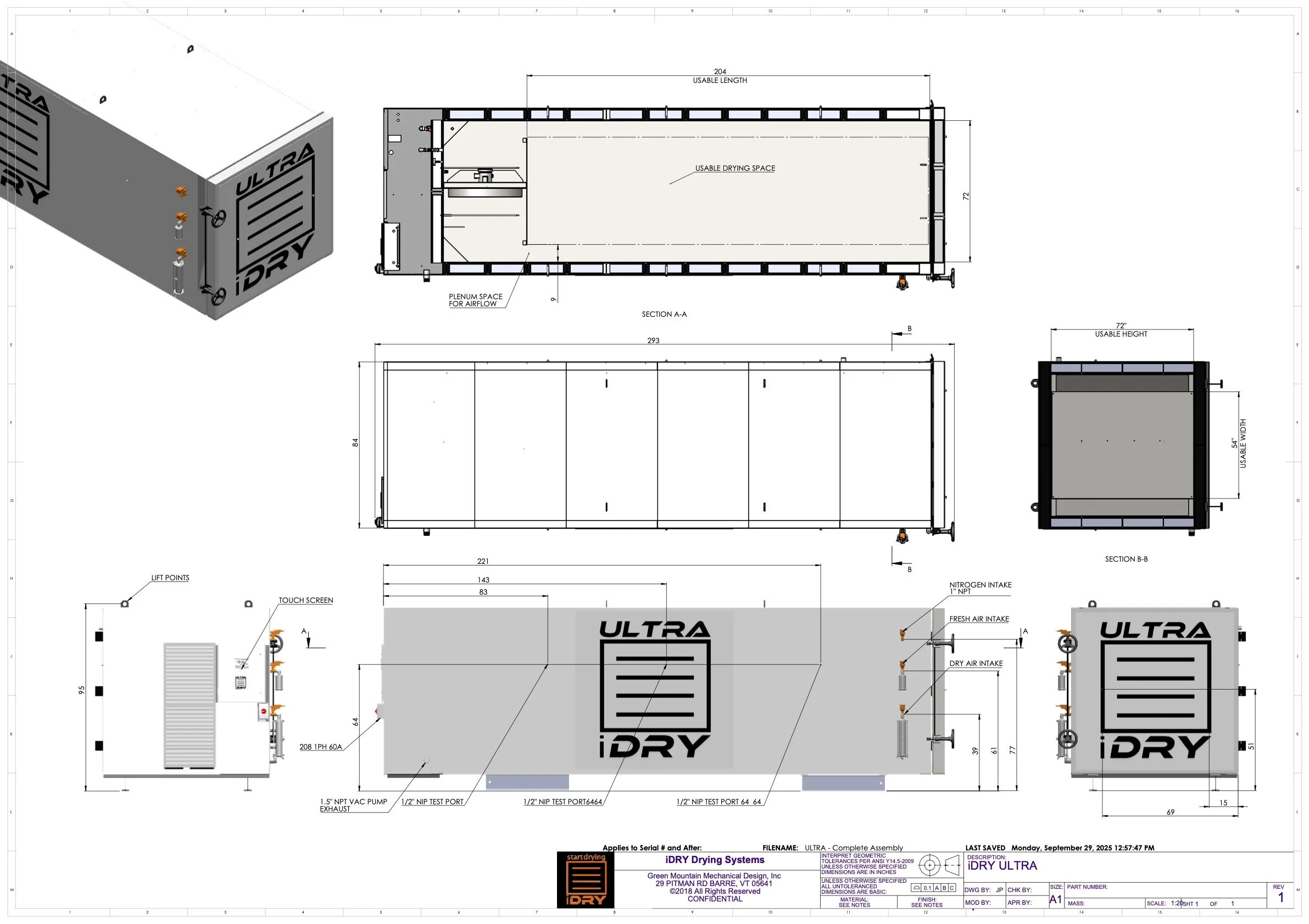

Capacity volume: 460 cubic feet

Power Requirement: 208-240VAC, 1PH, 60A (Electric)

Fully Reversible Fan: 2HP Kiln Duty Motor

Heat Power: 6kw

Humidity Sensor: Capacitive

Temperature Sensor: RTD

Loading: Hand, Tray or Forklift loaded

Max Temp: 180F

Controls: PLC w/ HMI TouchScreen

Total Weight of Equipment: 14,000lbs -

4-6 weeks Lead time

Shipped via Flatbed trailer

-

Non-stick airflow optimized self stacking trays