Ceramics & Powder Metals

Vacuum Drying for Ceramics & Powder Metals: Integrity, Precision, and Yield

Overview

Advanced ceramics and powder metallurgy parts are increasingly used in aerospace, defense, medical, and energy applications. But before these parts can be sintered, machined, or assembled, moisture and binders must be carefully removed — without cracking, warping, or internal stress.

iDRY vacuum drying systems offer a controlled, low-temperature solution for delicate green bodies, fragile geometries, and high-performance powders — improving product integrity and production efficiency.

“Using iDRY, we eliminated hairline cracks in our ceramic cores and improved binder removal uniformity. This reduced part rejection and saved multiple post-processing steps.”

— Technical Director, Advanced Materials Supplier

⚙️ How iDRY Vacuum Drying Works

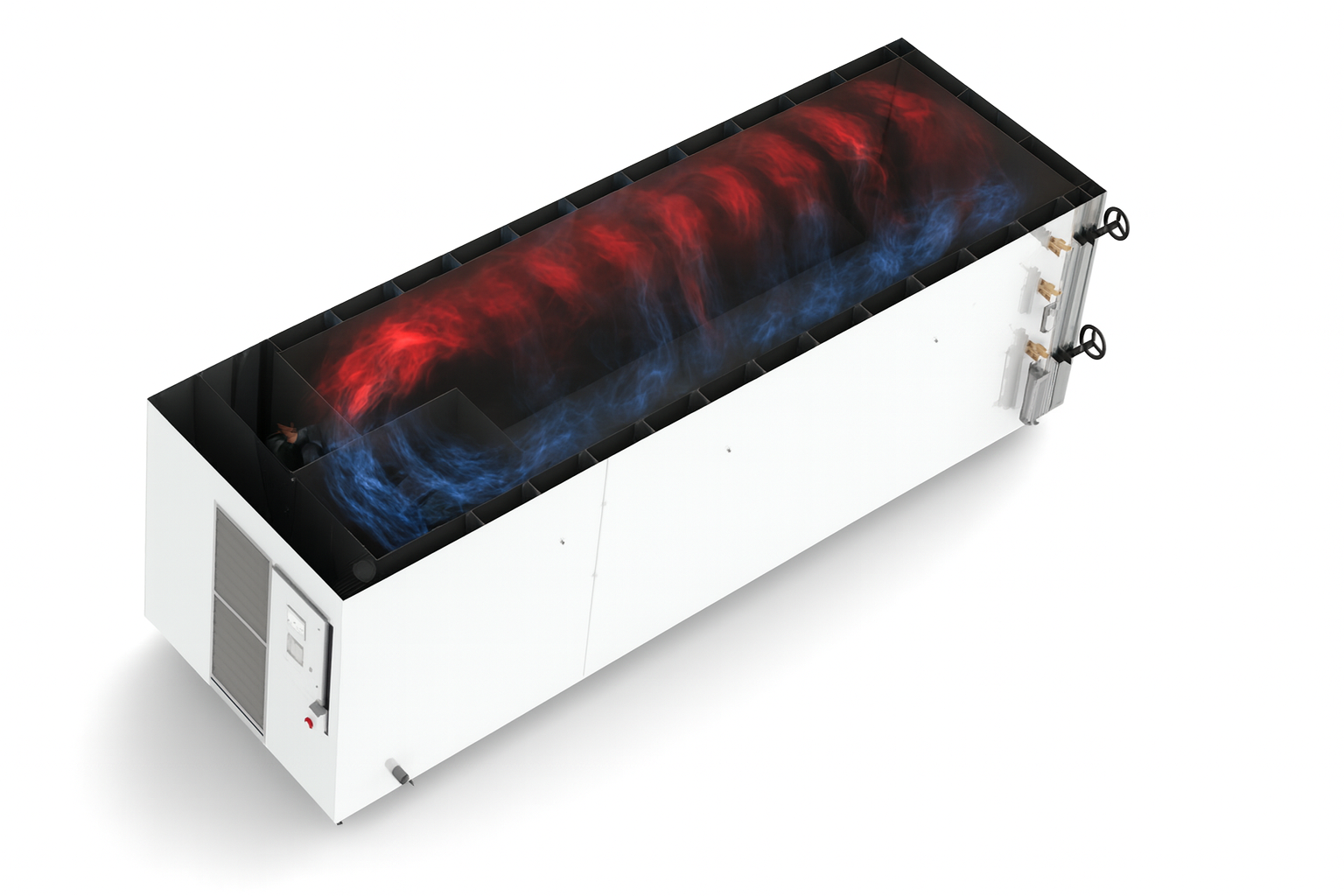

iDRY systems pull moisture and volatile compounds out of ceramic and powder-based parts under deep vacuum. This allows drying at significantly lower temperatures, reducing stress on fragile green components and porous structures.

Gentle, reversible airflow and real-time controls ensure uniform drying — critical for parts with fine internal features or complex geometries.

✅ Key Benefits:

Low-temperature drying prevents micro-cracking and distortion

Precise binder removal for powder metal and ceramic parts

Vacuum down to 2 inHgA for deep moisture extraction

Uniform airflow ideal for complex shapes or high-density trays

Full data logging for quality control and traceability

Supports pre-sinter, pre-machining, or packaging readiness

Ideal Applications Include:

Ceramic cores and investment casting molds

Technical ceramics (alumina, zirconia, silicon nitride)

Binder jet 3D printed metal parts (green stage)

Carbide, tungsten, and specialty alloy powders

Porous filters, insulators, and thermal components

Additive manufacturing (MIM/CIM/AM) parts

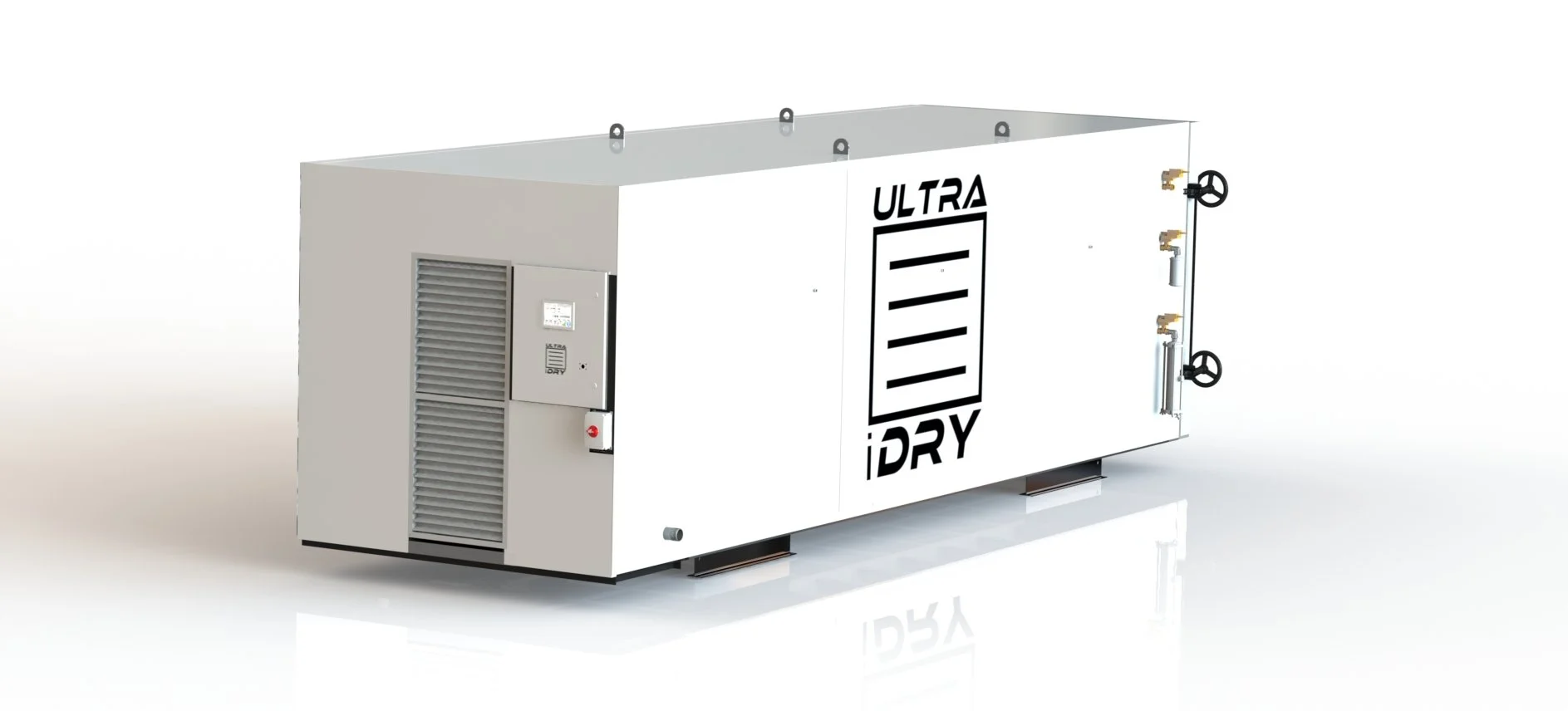

iDRY Ultra Vacuum Dryer – Ceramics & Powder Metals

Precision Drying for Advanced Materials

The iDRY Ultra is a vacuum drying system engineered for the unique challenges of ceramics, powders, and sintered metals. Using our unique patented vacuum technology, the system provides unmatched control over residual moisture and volatiles—achieving any dryness specification at any process temperature without compromising material integrity.

For powders and green ceramics, even trace amounts of moisture can lead to cracking, voids, or poor sintering. The iDRY Ultra enables manufacturers to remove bound and surface moisture uniformly, ensuring dimensional stability, strength, and reliable downstream processing.

Key Benefits

Controlled Dryness – Achieve precise moisture levels to prevent cracking, warping, or porosity.

Unique Patented Vacuum Process – Removes water and volatiles at low temperatures to preserve particle chemistry and structure.

Consistency & Uniformity – Repeatable results across batches, particle sizes, and material forms.

Enhanced Performance – Improves density, bonding, and mechanical properties of sintered parts.

Flexible Applications – Suitable for technical ceramics, advanced powders, and additive manufacturing feedstocks.

With the iDRY Ultra, manufacturers can ensure that ceramic components, powders, and powder metal parts meet the highest standards of quality, reliability, and performance in industries where precision matters most.

-

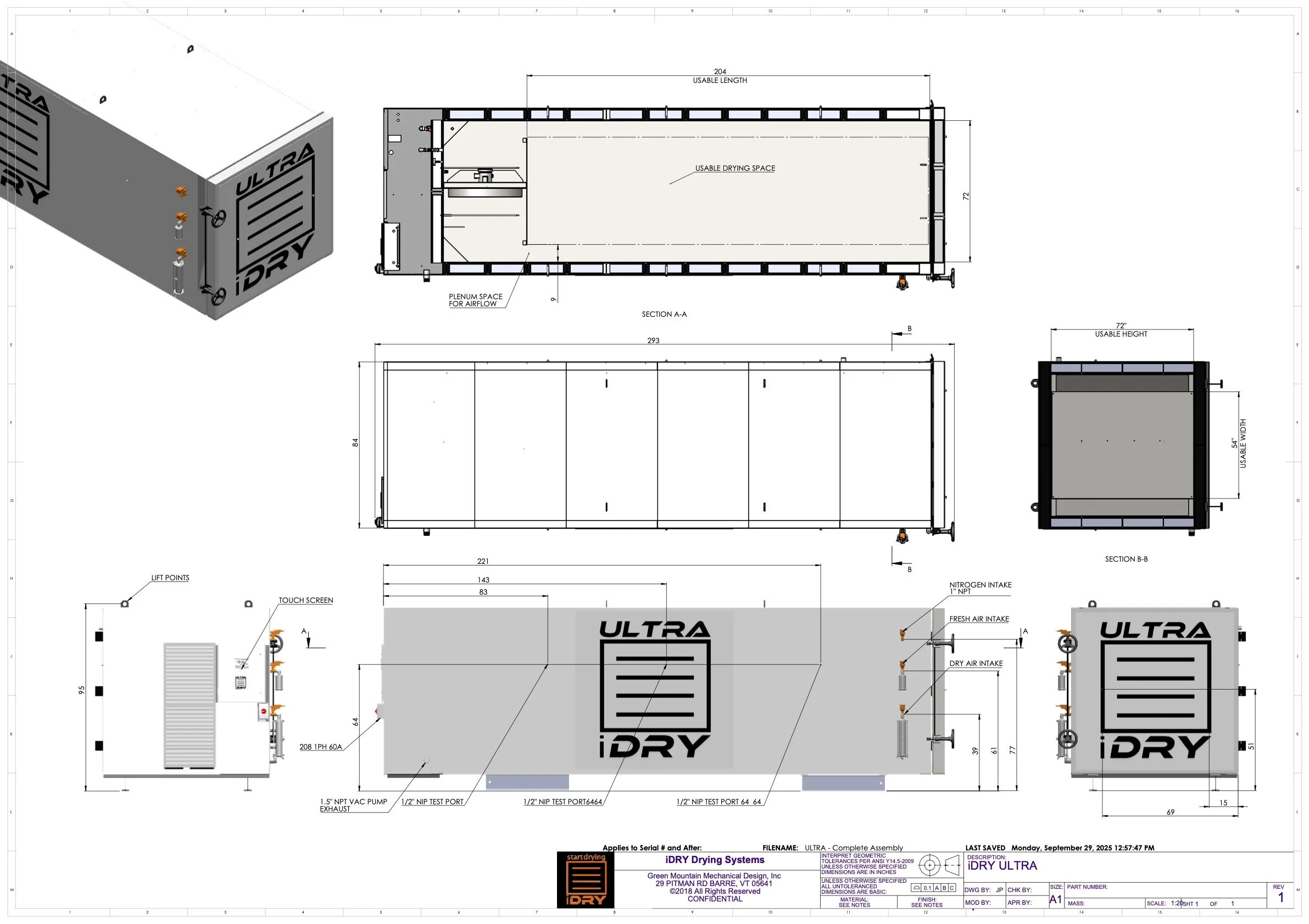

Capacity volume: 460 cubic feet

Power Requirement: 208-240VAC, 1PH, 60A (Electric)

Fully Reversible Fan: 2HP Kiln Duty Motor

Heat Power: 6kw

Humidity Sensor: Capacitive

Temperature Sensor: RTD

Loading: Hand, Tray or Forklift loaded

Max Temp: 180F

Controls: PLC w/ HMI TouchScreen

Total Weight of Equipment: 14,000lbs -

4-6 weeks Lead time

Shipped via Flatbed trailer

-

Non-stick airflow optimized self stacking trays