Electric Aviation & eVTOL

Vacuum Drying for Electric Aviation & eVTOL: Performance, Safety, and Compliance

Overview

eVTOL manufacturers and electric aircraft developers face unique challenges in scaling production: lightweight composite components, battery enclosures, and insulation materials must be dried thoroughly to meet structural, thermal, and safety requirements.

iDRY vacuum drying systems deliver moisture control and outgassing performance for next-gen flight systems — with precision, scalability, and aerospace-grade consistency.

“Drying composite rotor blades with iDRY gave us faster cycle times and tighter moisture control — without overbaking or dimensional shift. It’s built like flight-grade hardware should be.”

— Lead Composites Engineer, eVTOL Manufacturer

⚙️ How iDRY Vacuum Drying Works

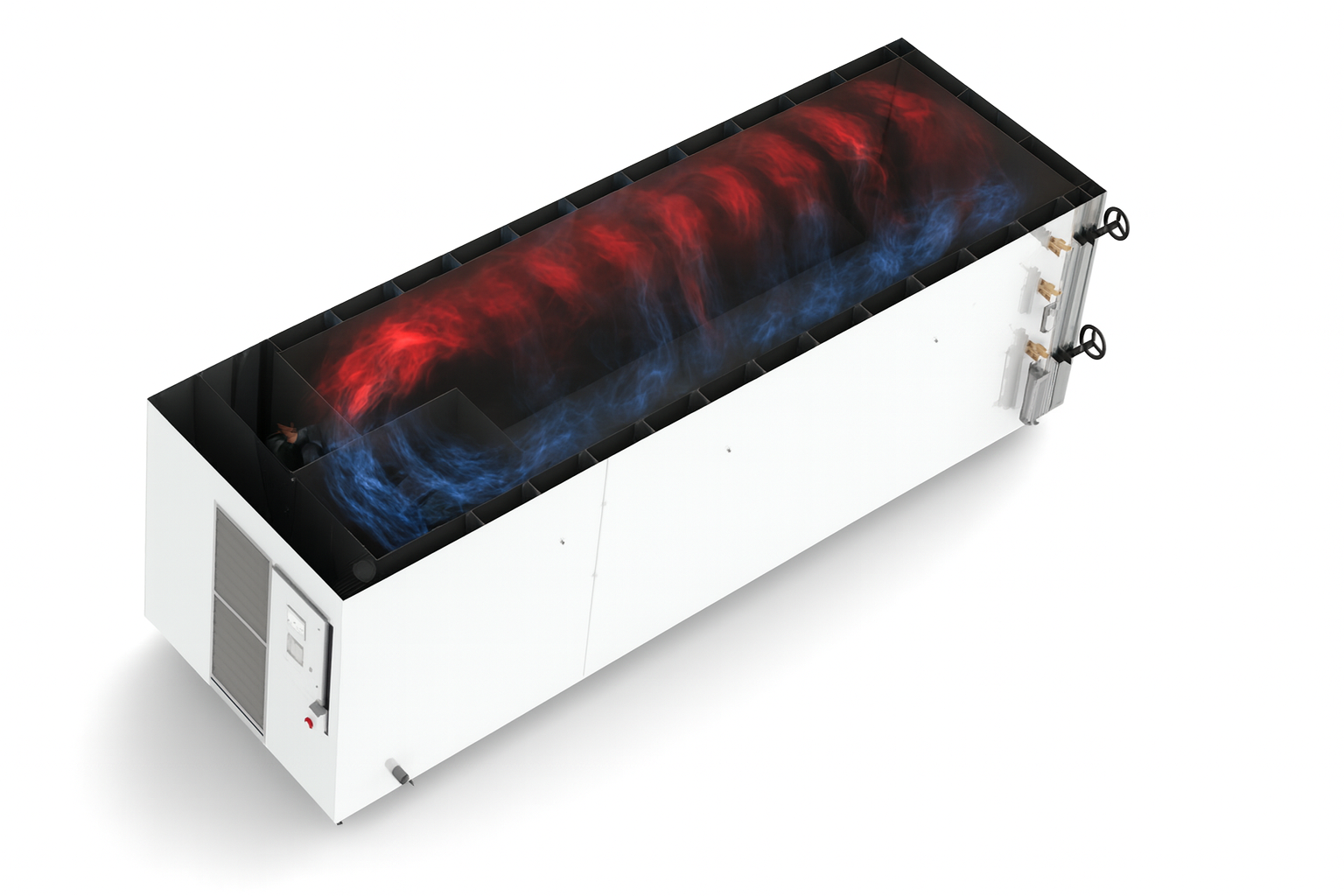

iDRY systems use deep vacuum to reduce the boiling point of water and volatiles inside advanced materials. Under vacuum, moisture is removed at low temperatures, without damaging fibers, resins, or adhesives.

Even airflow and reversible fans ensure uniform drying across complex shapes like blades, skins, and multilayer structures. The fully enclosed chamber also prevents contamination — crucial for safety-critical parts.

✅ Key Benefits:

Precision drying of carbon fiber, thermosets, adhesives, and foams

Moisture removal at low temp = no warping or resin degradation

Critical for battery modules, blades, airframe panels, and insulation

Supports pre-bond, post-cure, and outgassing prep

Vacuum levels down to 2 inHgA for deep drying

Full data logging and process traceability

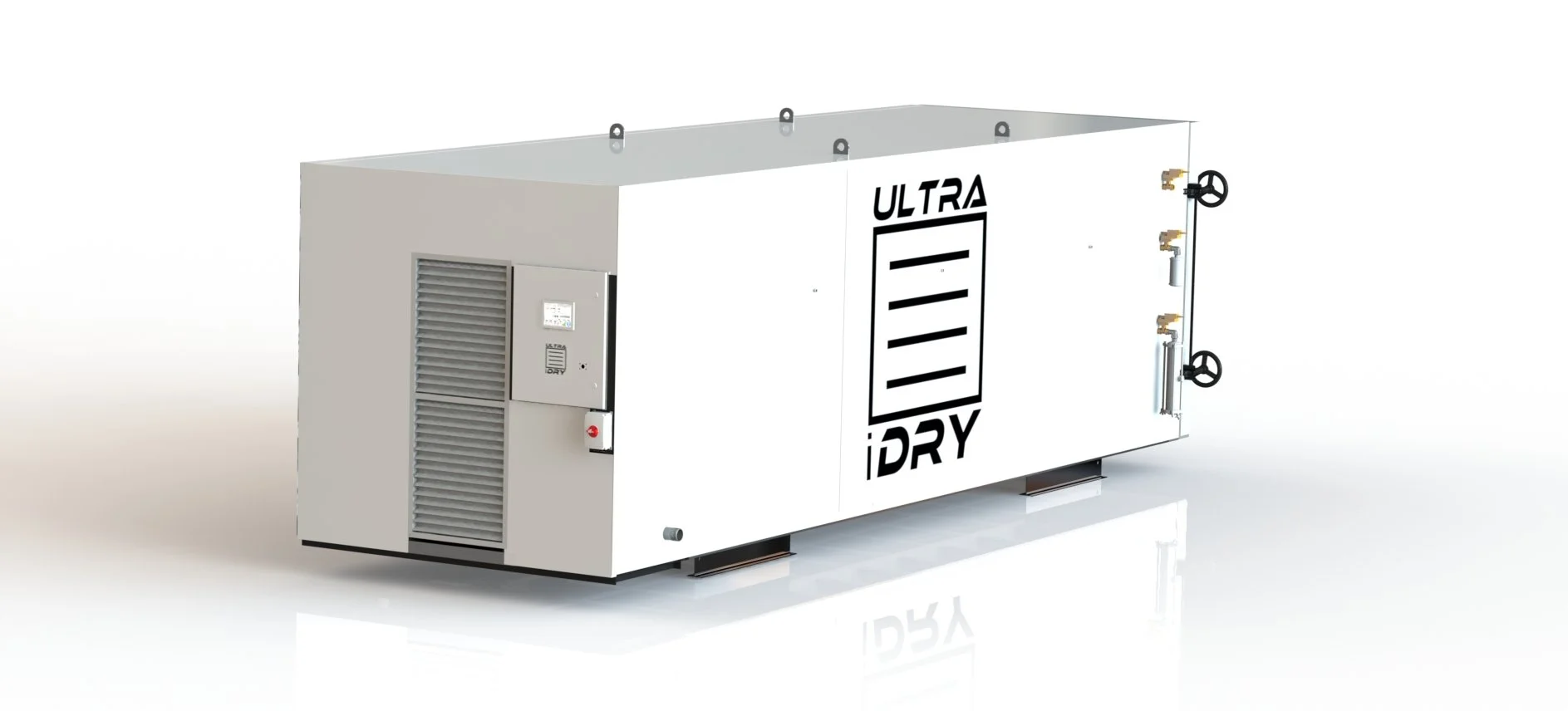

iDRY Ultra Vacuum Dryer – eVTOL & Advanced Air Mobility

Lightweight. Reliable. Flight-Ready.

The iDRY Ultra is a precision vacuum drying system engineered for the next generation of electric vertical takeoff and landing (eVTOL) aircraft. Using our unique patented vacuum technology, the system delivers complete control over moisture and volatiles in advanced composites, adhesives, and battery-related components—ensuring safety, reliability, and performance in flight-critical parts.

Unlike conventional ovens, the iDRY Ultra enables any target residual moisture level to be achieved at any temperature, protecting sensitive resins, polymers, and bonded structures from thermal degradation. This ensures that every component—structural or electrical—meets the strict tolerances required for aviation safety and long-term performance.

Key Benefits

Unique Patented Vacuum Process – Achieve moisture and volatile removal at controlled low temperatures.

Protect Material Integrity – Preserve fiber strength, resin chemistry, and bond line quality.

Enhanced Flight Safety – Eliminate trapped gases or residual solvents that can cause in-service failures.

Lightweight Reliability – Support the production of lighter, stronger, and safer airframe and propulsion components.

Scalable & Flexible – Configurations for R&D, prototyping, and full-scale eVTOL production programs.

As eVTOL and advanced air mobility move from concept to reality, the iDRY Ultra ensures materials and components are prepared to the highest possible standard—safe, stable, and ready for flight.

-

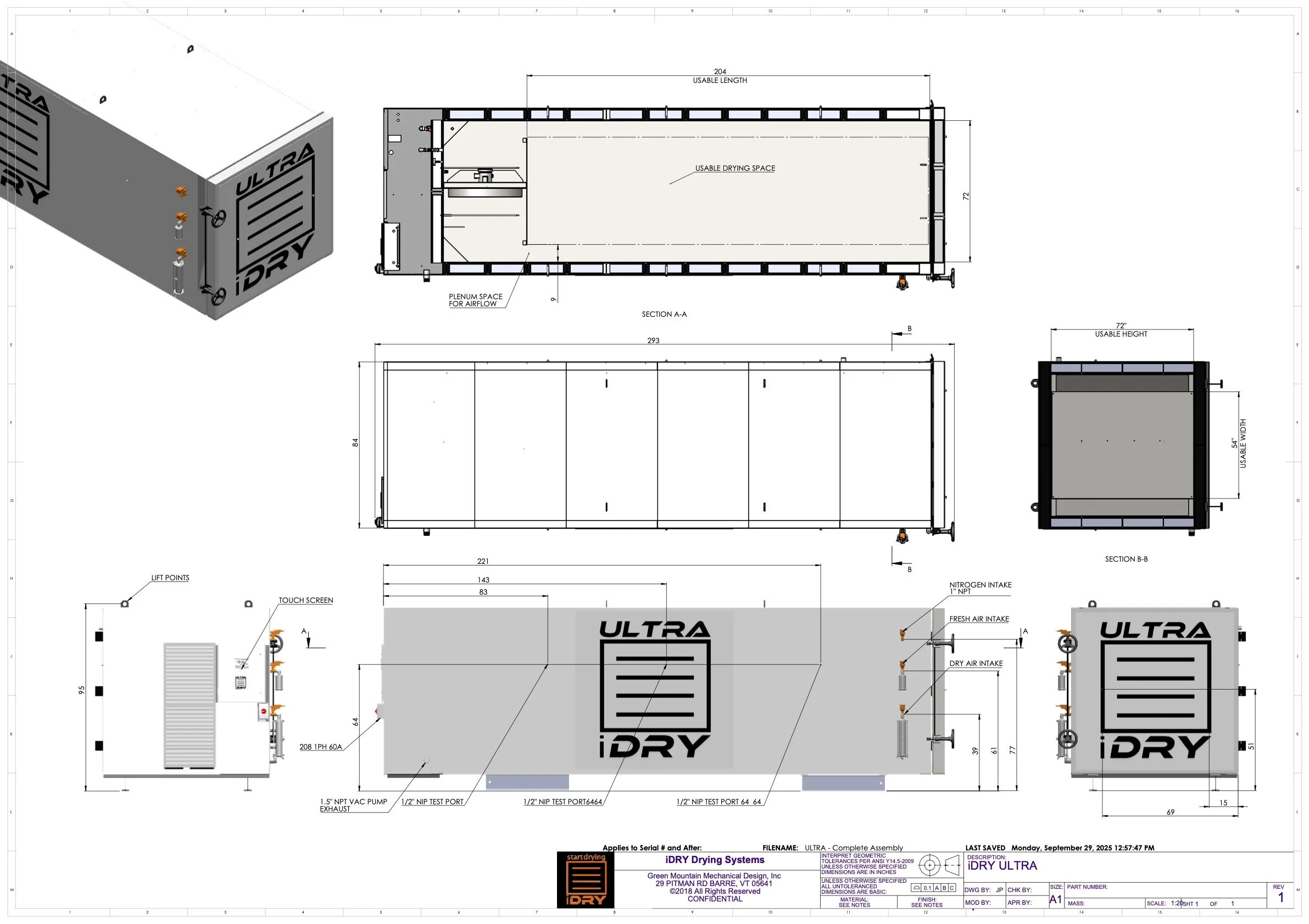

Capacity volume: 460 cubic feet

Power Requirement: 208-240VAC, 1PH, 60A (Electric)

Fully Reversible Fan: 2HP Kiln Duty Motor

Heat Power: 6kw

Humidity Sensor: Capacitive

Temperature Sensor: RTD

Loading: Hand, Tray or Forklift loaded

Max Temp: 180F

Controls: PLC w/ HMI TouchScreen

Total Weight of Equipment: 14,000lbs -

4-6 weeks Lead time

Shipped via Flatbed trailer

-

Non-stick airflow optimized self stacking trays