Nuclear & Energy

Vacuum Drying for Nuclear & Energy: Purity, Precision, and Process Control

Overview

Advanced energy systems — including nuclear fuel cycle components, clean tech infrastructure, and composite pressure vessels — require ultra-low moisture content for reliable performance and regulatory compliance. Whether preparing carbon fiber tubes for uranium enrichment or drying components for high-vacuum environments, even trace moisture can degrade performance or cause failure.

iDRY vacuum drying systems provide controlled, scalable drying for critical energy materials — ensuring repeatable low-moisture results, material integrity, and environmental isolation.

Dry carbon fiber tubes to below less than 0.01 grains moisture at 180°F under vacuum. iDRY delivered a tunable, automated solution that matched our process window and outperformed oven-based drying.

⚙️ How iDRY Vacuum Drying Works

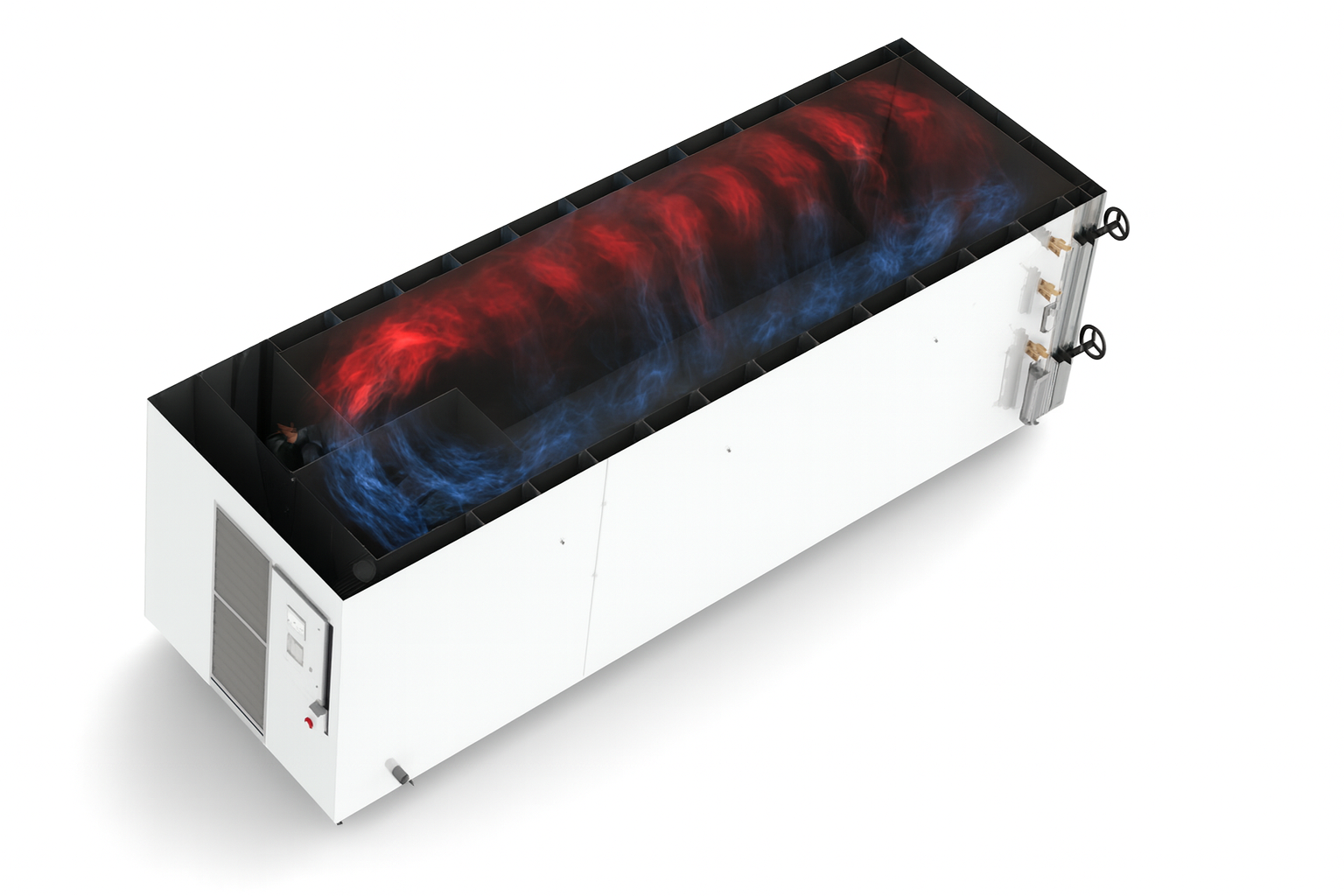

iDRY systems create a low-pressure environment that reduces the boiling point of water, enabling effective moisture removal at lower temperatures. Under vacuum, trapped water and volatiles are pulled from deep inside materials — even from resin-rich, multi-layered, or porous structures — without thermal stress or surface oxidation.

Fans, heat, and airflow can be precisely controlled, while cycle data is automatically logged to support process validation and QA documentation.

✅ Key Benefits:

Deep vacuum drying (down to 2 inHgA) for moisture-critical applications

Compatible with 180°F long-duration cycles (e.g., 5 days)

Ideal for carbon fiber tubes, composite structures, and ceramics

Lower drying temperatures = reduced material degradation risk

Fully automated cycles with data logging and batch reporting

Scalable chamber designs for high-throughput or long-length components

Nuclear & Energy Applications Include:

Drying carbon fiber tubes used in uranium enrichment

Vacuum drying of composite pressure vessels and structural supports

Moisture removal from ceramic insulators, shielding, or AM parts

Degassing of polymer-lined or resin-impregnated components

Final prep of vacuum hardware for fuel handling or containment

Pre-treatment for parts entering radioactive or high-temperature environments

Sublimation and de-sublimation hot and cold boxes

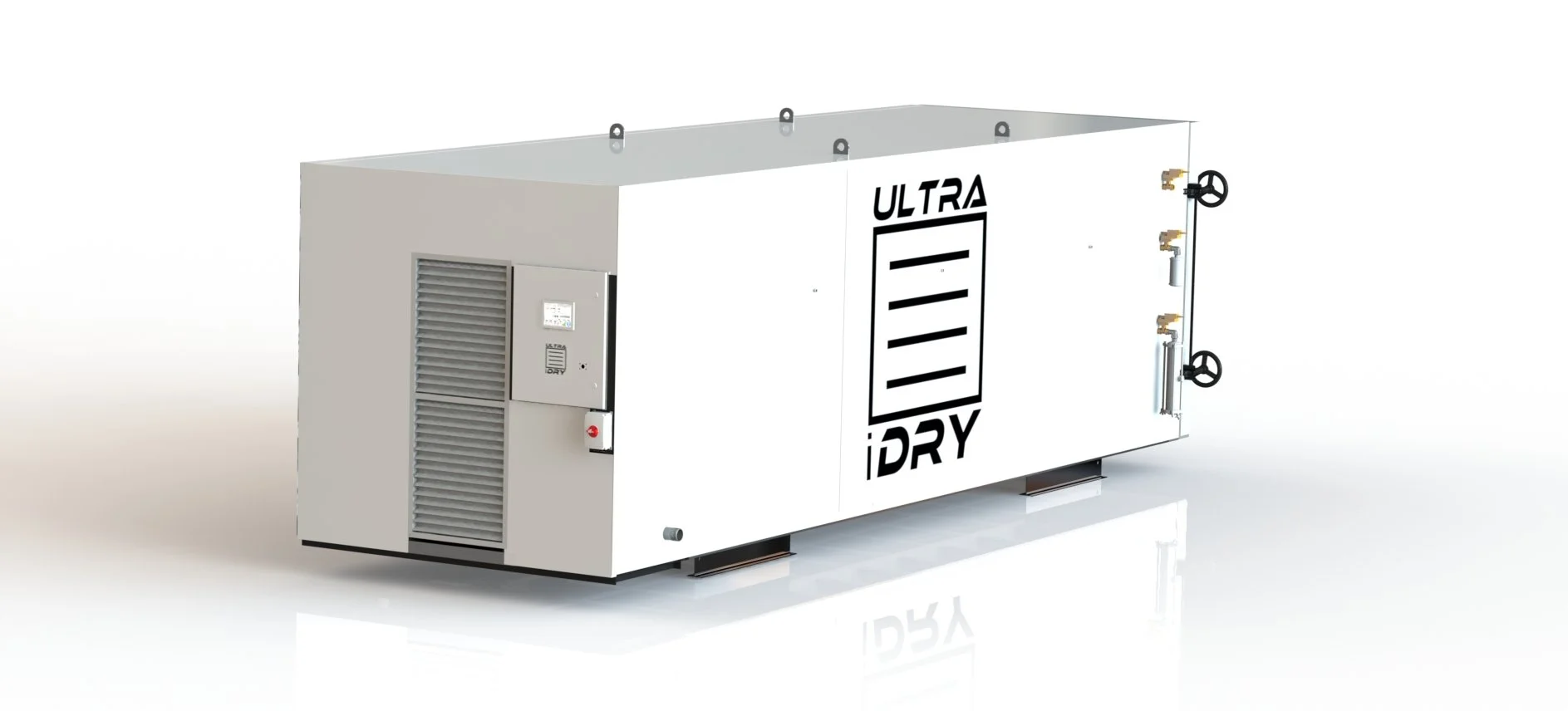

iDRY Ultra Vacuum Dryer – Nuclear Energy

Ultra-Dry Precision for Nuclear industry applications

The iDRY Ultra is a next-generation vacuum drying system engineered to achieve ultra-low residual moisture content in materials, components, and containers that may come in contact with Uranium Hexafluoride (UF6). Designed for the most demanding environments, it combines a unique patented vacuum technology with precise temperature control to ensure compliance with stringent regulatory and safety standards.

From drying carbon fiber composites used in enrichment processes to conditioning UF₆ cylinders and specialty materials, the iDRY Ultra enables complete control of moisture levels at any temperature. By reducing water activity and eliminating trapped volatiles, the system helps extend component life, ensure material stability, and maintain the highest level of process safety.

Key Benefits

Ultra-Low Moisture Targets – Reach required dryness levels (e.g., sub-ppm or specific grains/ft³) to meet nuclear standards.

Process Integrity – Dry at controlled low temperatures to protect material integrity and prevent degradation.

Regulatory Compliance – Supports stringent quality systems (NQA-1, ASME, IA9100) for nuclear-grade processing.

Safety & Reliability – Eliminate residual water that could cause unwanted reactions, corrosion, or off-gassing.

Scalable Systems – Configurable for lab R&D, pilot programs, and full-scale nuclear fuel operations.

The iDRY Ultra ensures precision, repeatability, and safety in drying processes critical to the nuclear supply chain—where moisture control is directly tied to reliability and compliance.

-

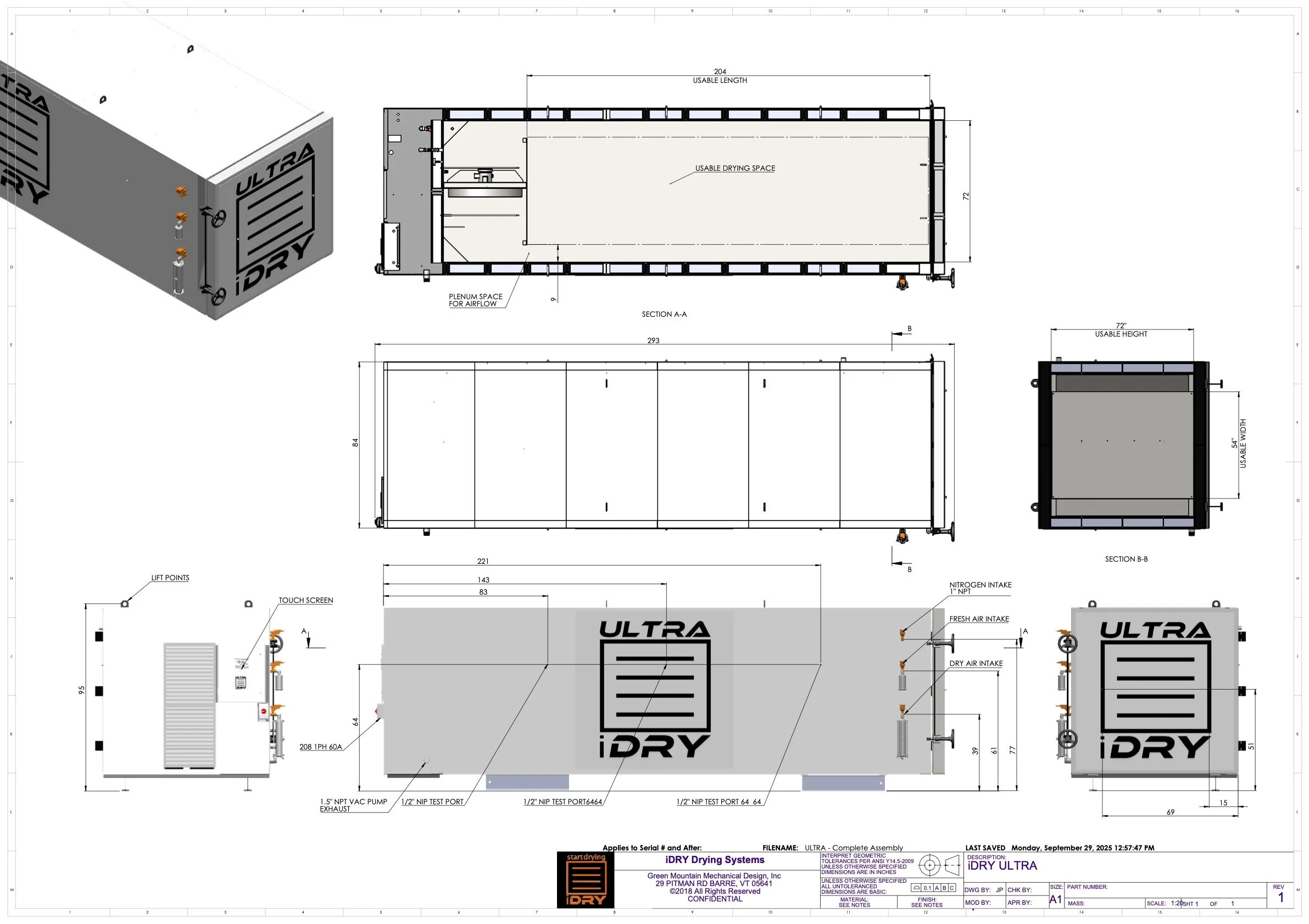

Capacity volume: 460 cubic feet

Power Requirement: 208-240VAC, 1PH, 60A (Electric)

Fully Reversible Fan: 2HP Kiln Duty Motor

Heat Power: 6kw

Humidity Sensor: Capacitive

Temperature Sensor: RTD

Loading: Hand, Tray or Forklift loaded

Max Temp: 180F

Controls: PLC w/ HMI TouchScreen

Total Weight of Equipment: 14,000lbs -

4-6 weeks Lead time

Shipped via Flatbed trailer

-

Non-stick airflow optimized self stacking trays

$129,000

$5000 Deposit